Solar power plants face issues due to temperature and environmental factors, which lead to reduced efficiency and potential major breakdowns if not addressed quickly. The challenge is that monitoring tools like drones, digital multimeters, and infrared cameras are costly, making regular checks infrequent, which does not allow quick responses to problems. This means that if a problem arises after a maintenance check, electricity production efficiency will fall, leading to significant losses.

The ability to quickly respond to problems is what plants with constant energy production need.

One of the ways to achieve a quick response to problems is through the use of anomaly detection. Using this method provides an opportunity to respond to problems quickly and significantly reduces the spending on third-party equipment.

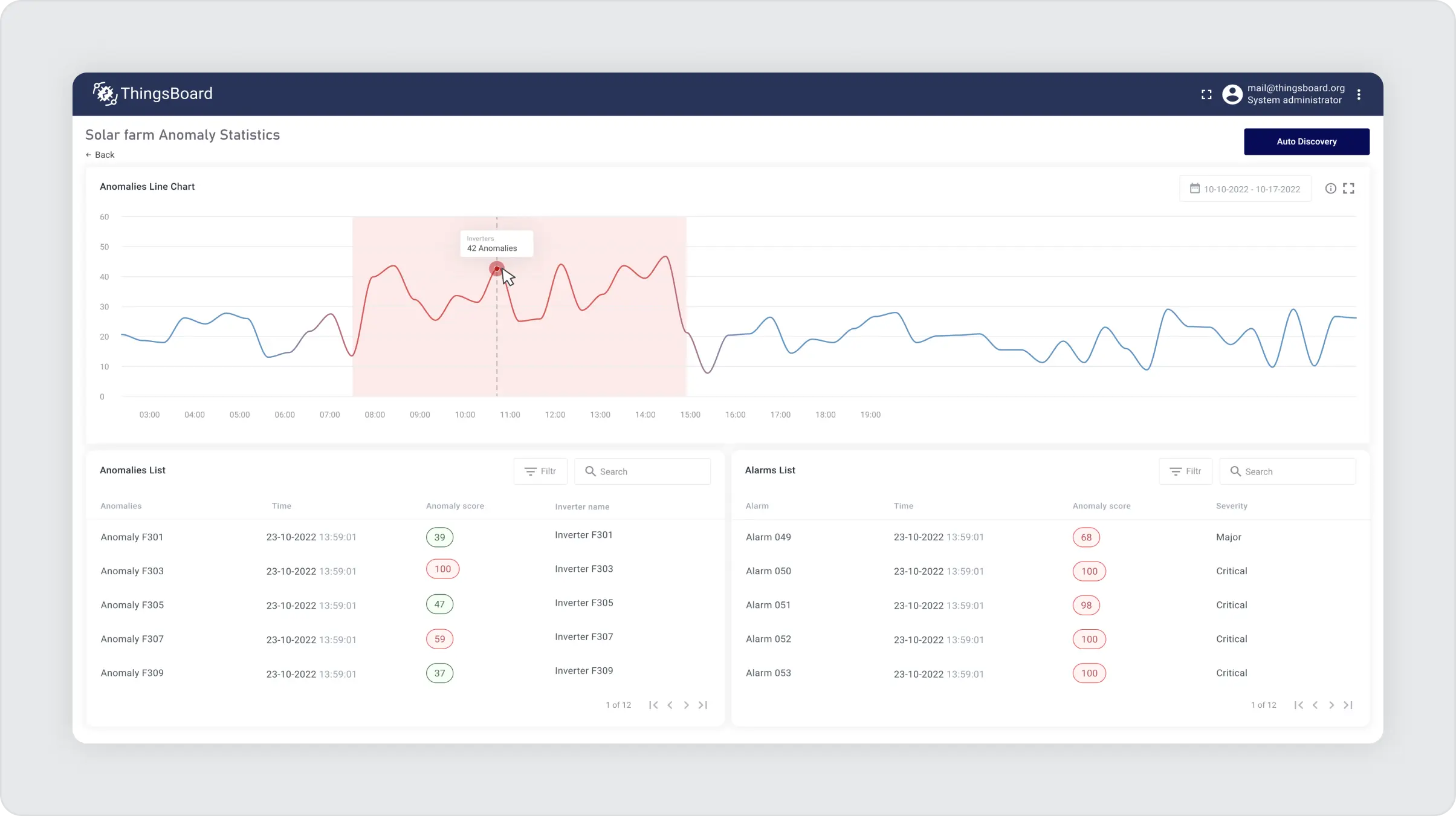

Anomaly detection is a technique to identify patterns or events deviating from the norm. In the context of a solar farm, this can involve monitoring various factors, such as Real-time Energy Output, Power Generation Trends, Solar Irradiance, and Temperature for Solar Panels. Also Output Voltage and Current, Frequency, Efficiency, Temperature for Inverter. By analyzing this data, anomaly detection algorithms can identify unusual patterns or events that may indicate problems before they can do any damage to the solar panel or inverter. In other words, we look for a problem not when we see that energy is produced less than expected for the second day in a row but right at the moment when the problem appeared.

But, unusual patterns are not just deviations of parameters from the norm.

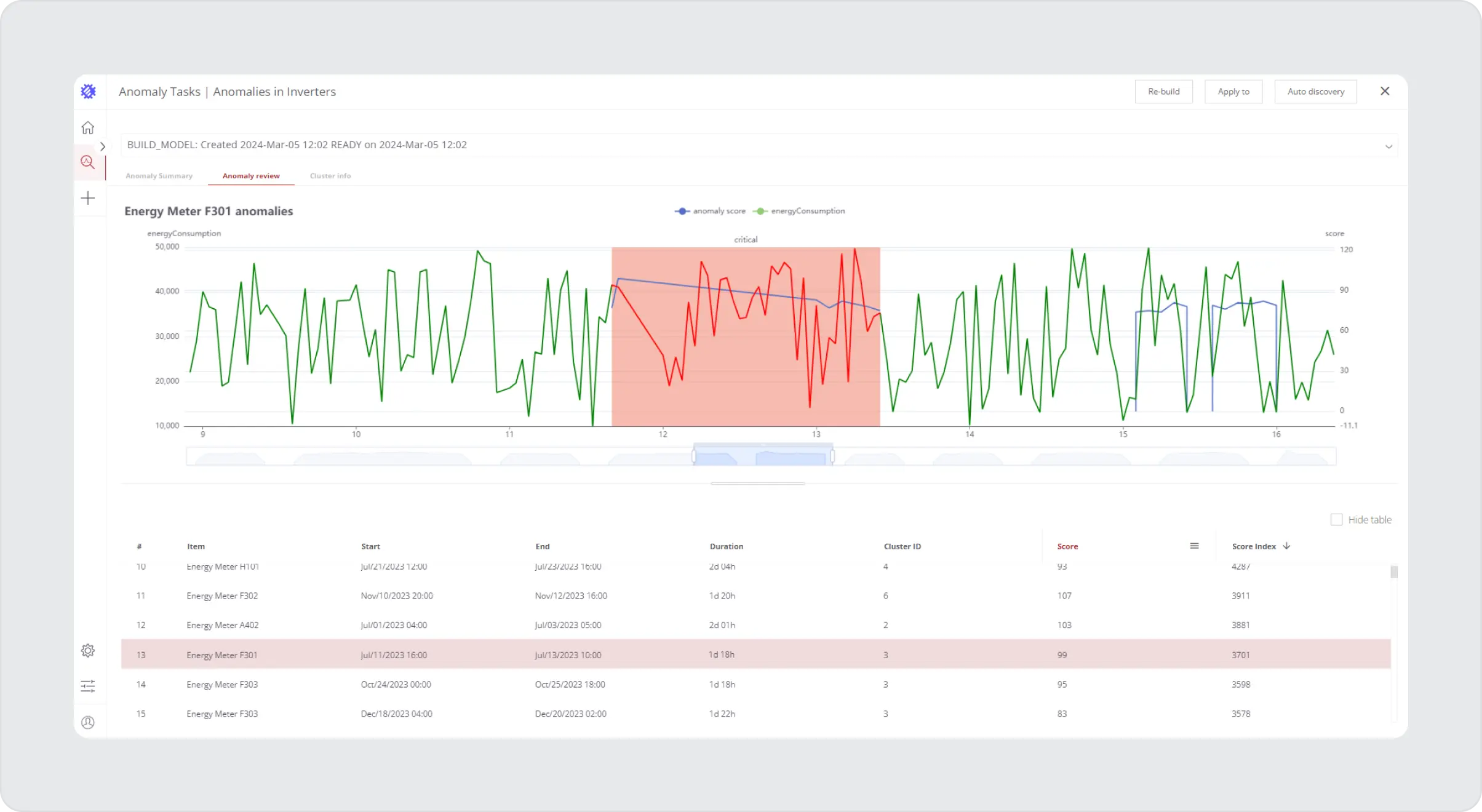

Unusual patterns are combinations of parameters that are not expected but which identify potential problems. They are discovered by analyzing historical data collected from solar panels and inverters. During this analysis, we focus not only on individual parameter values but on a combination of values because it potentially gives more insights into system behavior. Based on this, it is possible to find current problems and predict future ones.

A person cannot cope with the calculations of such data arrays. That is why we need advanced analytics with machine learning capabilities to analyze historical data and find unusual patterns in real-time.

Now, we will show how to configure Trends Analytics for correct anomaly detection. However, before that, let’s consider what types of anomalies occur in Solar Farms.

Overview of common anomalies in the equipment of solar power plants

The most widespread and important problems for us are those with solar panels and inverters since these are the first frontier of obtaining energy. Therefore, we will look for anomalies in these parts of the power plant.

Anomalies in photovoltaic modules

Below, the most common breakdowns in PV modules and solar panels, which can be quickly and economically solved if they are dealt with immediately, will be described.

Most of them are formed on separate panels, so a drop in the indicators of one panel in contrast to another will indicate a breakdown. You can find each of them by finding anomalies in the Output Electricity (voltage and current) and Power Production indicators from the solar panel.

- Soiling: Soiling refers to the accumulation of dirt, dust, bird droppings, or other materials on the surface of solar panels. This layer of grime can significantly reduce the panels’ ability to absorb sunlight, leading to decreased electricity production.

- Shading: Shading occurs when an object, such as a tree, building, or another solar panel, casts a shadow on a solar panel. This can lead to a reduction in the panel’s electricity production. Prolonged shadowing can lead to an imbalance in the solar panel system and may cause hot spots or reduce the overall lifespan of the panel.

- Delamination and Internal Corrosion: Moisture can find its way into the panel, causing internal corrosion, if the panels are not keeping out air and water and all the solar panel components are not laminated correctly.

- Identifying and Addressing Solar Panel Anomalies Faulty wiring, loose connections, corrosion, and oxidation can interfere with electricity production.

- Hot Spots: Badly-soldered connections can cause low resistance in the part of the panel that receives the power generated by the cell, leading to a hotspot in the soldered points and/or a cell. This phenomenon can ultimately lead to a short circuit, reducing the performance and lifespan of the PV panel.

- PID Effect: Potential-induced degradation (PID) can cause an ongoing reduction in performance and accelerated aging of the PV panel. PID occurs when the voltage potential between the solar cells and the grounded frame of the panel causes a leakage current that can damage the cells.

- Snail Trail Contamination: Snail trail contamination is a phenomenon where a white or grayish residue appears on the surface of the solar panel. This residue can reduce the performance of the panel and is caused by the release of silicone from the panel’s encapsulant material.

Tackling Anomalies in Inverters

Inverters are a very important link of a solar power plant, a breakdown of which can lead to the shutdown of the entire power plant. This can have a critical impact on the total efficiency and profitability of the power plant.

You can observe the operation of the inverter by following the indicators Output Voltage and Current, Frequency, Efficiency, and Temperature.

- Overheating: Inverters are sensitive to temperature, and high temperatures can reduce production and potentially a stoppage altogether if overheating occurs as the maximum operating temperature is reached. To prevent overheating, it is important to keep the switch cabinet and the area where the inverter is located well-ventilated, along with the inclusion of cleaning dust filters that can prevent any issues impeding airflow. You can monitor this problem with the help of indicators Temperature, Output Voltage, and Current.

- Isolation Short-Circuit Fault: If there is too much moisture or damage to the cabling sleeves, then an isolation short-circuit fault can occur, whereby the inverter will report an “isolation alarm”. In this scenario, the solar inverter will either work at the minimum “required” isolation level or stop working altogether. You can monitor this problem with the help of indicators Efficiency, Output Voltage, and Current.

- Inverter Does Not Restart: Inverters sometimes fail to restart after a power outage. Various factors, including a faulty inverter, a tripped circuit breaker, or a blown fuse, can cause this. You can monitor this problem with the help of indicators Frequency, and Efficiency.

- Maximum Power Point Tracking (MPPT) Module: The MPPT module is responsible for tracking the maximum power point of the solar panel array. If the MPPT module fails, the inverter cannot convert the DC electricity generated by the solar panels into AC electricity. You can monitor this problem with the help of indicators Temperature, Output Voltage, and Current.

Summary

Efficiency challenges in solar farm operations demand a proactive approach to problem-solving, particularly in the context of scheduled diagnostics and high equipment maintenance costs. Anomaly detection emerges as a cost-effective solution, leveraging historical data to identify deviations in parameters like Real-time Energy Output, Power Generation Trends, and Temperature for Solar Panels, along with Output Voltage, Current, Frequency, and Efficiency for Inverters. This approach helps quickly find current problems and predict future issues, which is important for keeping the energy production going without any interruptions.

To implement this approach, an efficient strategy involves creating anomaly detection models based on historical telemetry data, configuring real-time anomaly detection, and providing a comprehensive dashboard for the maintenance team. This ensures a streamlined process from anomaly identification to resolution, utilizing Trendz Analytics to enhance solar farm efficiency by minimizing downtime, reducing operational costs, and optimizing long-term performance.

And this is only part of how advanced analytics and machine learning can improve the efficiency of solar farms. With help, you can find solutions to your solar farm problems, including Soiling, Battery Health Diagnostics, and more.