What is oil tank level monitoring?

Oil tank level monitoring system is a specialized solution used to monitor and manage the amount of oil in one or more tanks. This system is essential in a variety of industries, including petrochemical, heating oil suppliers, and other sectors where oil storage is a critical component of the operational process. The oil tank monitoring system is done through smart technology, which includes flexible oil tank sensors and oil tank monitors, along with reliable communication methods to accurately monitor oil levels and an IoT platform to collect and show all data. This system involves the use of three essential components:

- Sensors to accurately monitor the oil level;

- The communication layer to transmit the data from sensors to the platform;

- Platforms to store, process, and display the data.

Accurate tank level and volume measurements are essential for businesses, especially petrol stations, which need the right amount of fuel to avoid running out of oil or overstocking. Insufficient control of oil levels can lead to operational issues, financial losses, and pollution in cases of oil spills.

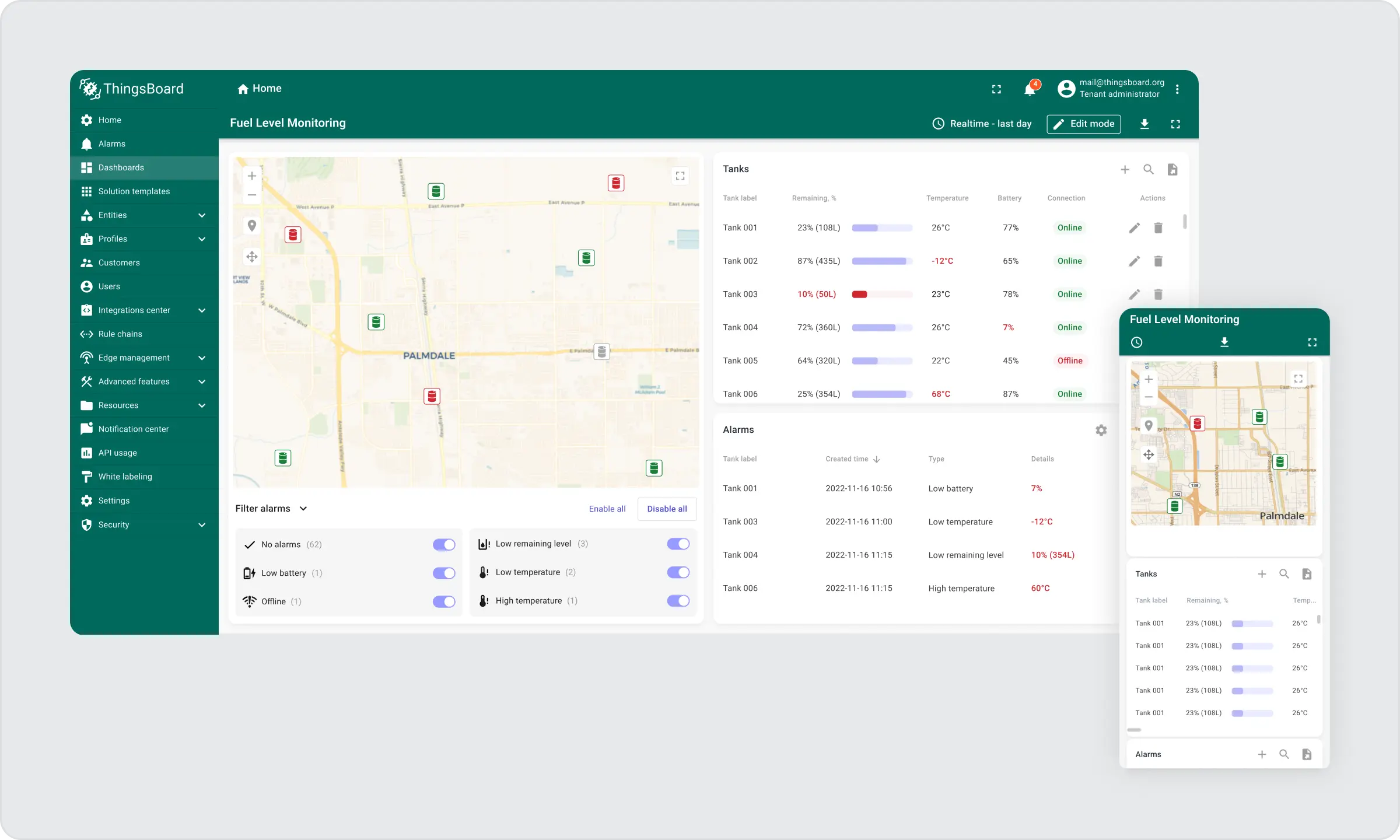

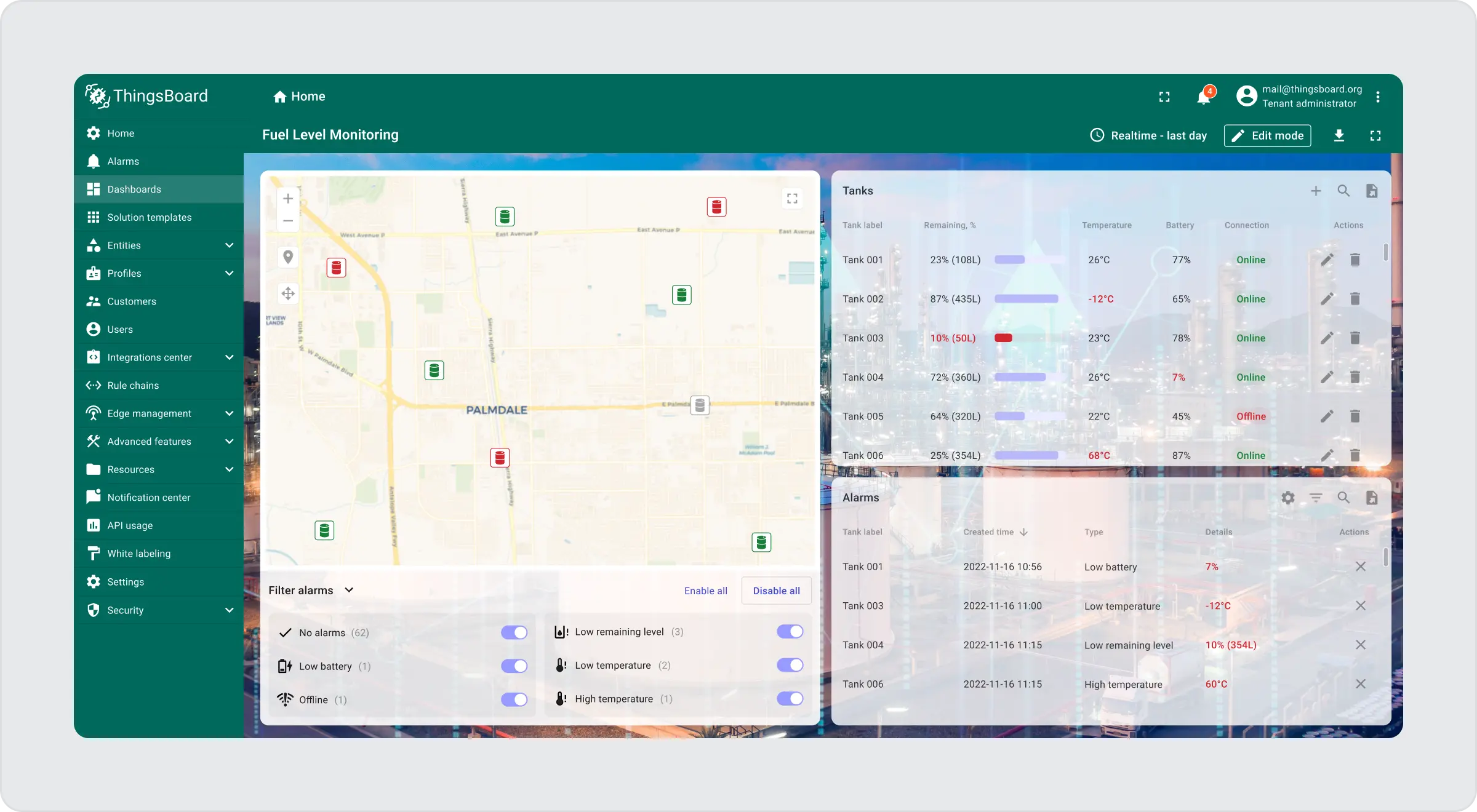

One of the most important components of an Oil tank level monitoring system is an IoT platform that can provide a 24/7 remote oil tank level monitoring solution by collecting and processing tank telemetry data from various sensors. A specially designed real-time dashboard shows how much oil the tank has right now, historical changes, and predicted usage, enabling efficient oil management and seamless operations. With the easy-to-use dashboard, you can quickly get all the tank information: side height, Diameter, Maximum capacity, and Tank level. When the sensor is installed, you can check the oil level, set up measurement and notification methods, and see how much oil you use. Effective oil management and alerts of predicted run-out dates will help avoid interruptions, ensure oil availability when needed, improve business sustainability, and ensure environmental guidelines by detecting tank leaks, making operations more efficient.

How oil tank level monitoring system works?

An oil level monitoring system comprises three mandatory components: data measurement, transmission, and display. There are a large number of oil level sensors available – smart Wi-Fi tank level monitoring systems, tank content gauges, visual oil level gauges, clock oil level gauges, and electronic oil tank monitors, all of which perform the same function – read the contents remaining in an oil tank. The sensor is mounted on the lid of a closed tank or suspended by a rod or rope over an open tank. Once installed, the sensor can check the amount of liquid in the tank and related telemetry. To do this, it sends a wave through the liquid and measures the time it takes for the wave to reflect off the liquid surface.

After the sensor measures the liquid level, the data is transmitted to a central monitoring system or controller via wireless technology such as Wi-Fi, Bluetooth (BLE), LoRaWAN, NB-IoT, or cellular networks.

The data is displayed on local readouts or integrated into the IoT visualization platform. The platform provides a tank monitoring dashboard with real-time data visualization, historical trend analysis, and automated alerts for low levels or rapid changes that may indicate leakage or theft.

This allows you to monitor oil levels remotely from anywhere in the world via a web or smartphone app, making it easy to keep track of the amount of liquid in any tank. This is very important for tanks in the field, tanks below ground, and other tanks located in hard-to-reach places.

IoT based Platform for oil tank monitoring

IoT devices for wireless tank monitoring can be used to remotely control and accurately and repeatably read oil tank level readings. These devices use a variety of sensors and communication technologies to transmit data on oil level, temperature, and sometimes even oil quality to a central system or directly to users via a monitoring platform in real-time.

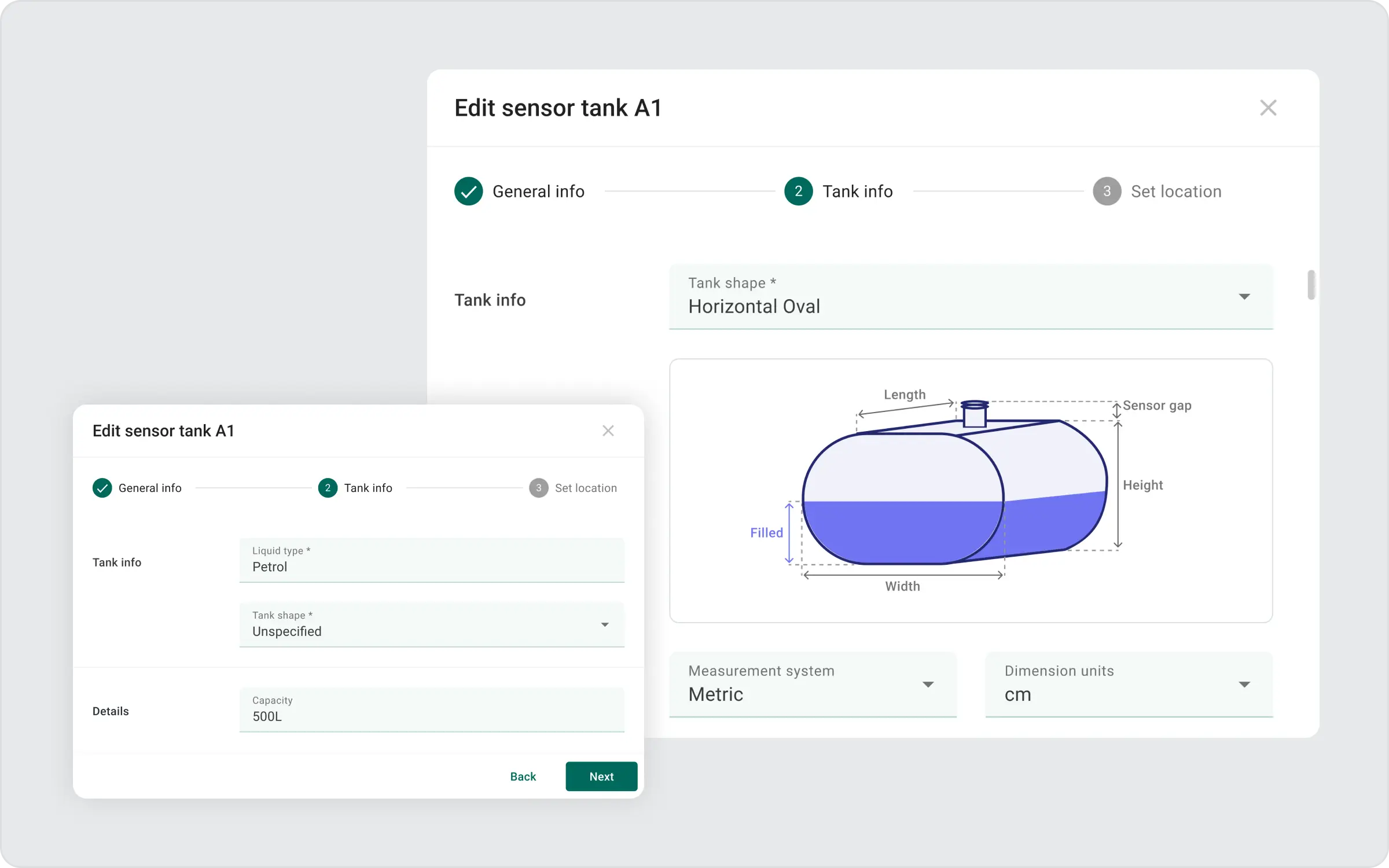

However, the determination of oil level is not solely based on sensor measurement. It also considers the tank’s shape and dimensions, which are crucial for accurate calculations for the different-sized tanks. Sometimes, sensors transmit data in one unit of measurement while the tank dimensions are in another. In such cases, the IoT platform plays a crucial role. It enriches the raw readings from the sensors by applying mathematical calculations that consider the specific tank dimensions and shape. The enriched data is then displayed on monitoring and end-user dashboards. The IoT platform efficiently handles the various interactions between devices and cloud-based data storage and applications. It supports connectivity, configuration, integration, and management of devices and data in the IoT ecosystem, allowing for remote monitoring and analysis of liquid levels from anywhere using a web application or smartphone. This system ensures continuous real-time tracking of fluid levels.

Using an IoT ThingsBoard platform to monitor oil tank levels offers many advantages. It allows you to obtain precise, real-time information and manage it efficiently, ensuring smooth and safe operations. With features like user management, device compatibility, and customizable options, a ThingsBoard platform is a versatile and powerful tool for any business involved in oil storage and management.

Explore capabilities one of the best IoT Visualization Platform

GET ACCESSHere is an overview of the main benefits of using an ThingsBoard IoT platform in the tank level monitoring:

Calculation level based on geometry

Determining the oil level is not only based on the sensor readings, but also takes into account the shape and dimensions of the tank, which are crucial for accurate calculations. The use of an ThingsBoard platform makes it possible to be more flexible in the choice of sensors, since sometimes sensors transmit data in some units of measurement, and the dimensions of the tank in others. In such cases, the IoT platform plays a crucial role. It enriches the raw readings from the sensors by applying mathematical calculations that take into account the specific tank dimensions and shape. The enriched data is then displayed on monitoring and end-user dashboards.

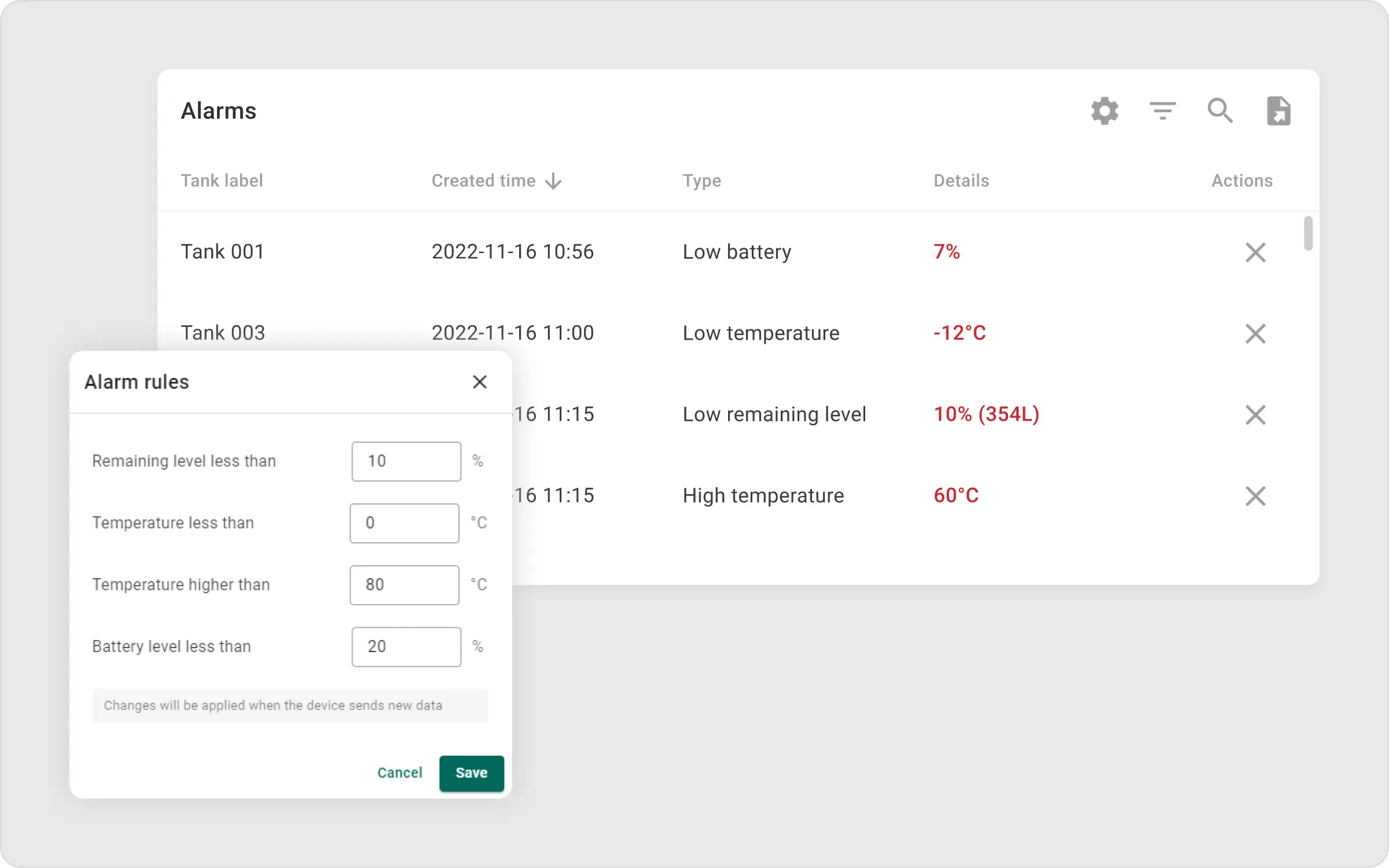

Alerting and Notification

The ThingsBoard IoT platform can continuously monitor the oil level and send alerts to phone or computer if the liquid level gets too low or too high. This helps take action quickly, such as refilling the tank or stopping the flow to prevent a spill. Users can set thresholds (e.g. Temperature range of the oil to be monitored, Pressure to be maintained in the storage tank ) for level alarms, receiving alerts via SMS, email or app when the oil level falls below a certain point or when unusual patterns are detected – allowing for timely oil topping up or maintenance or even control any thefts

The platform also allows to customize alerts based on needs and preferences – it can notify of changes in temperature, pressure, or any other changes in the tank.

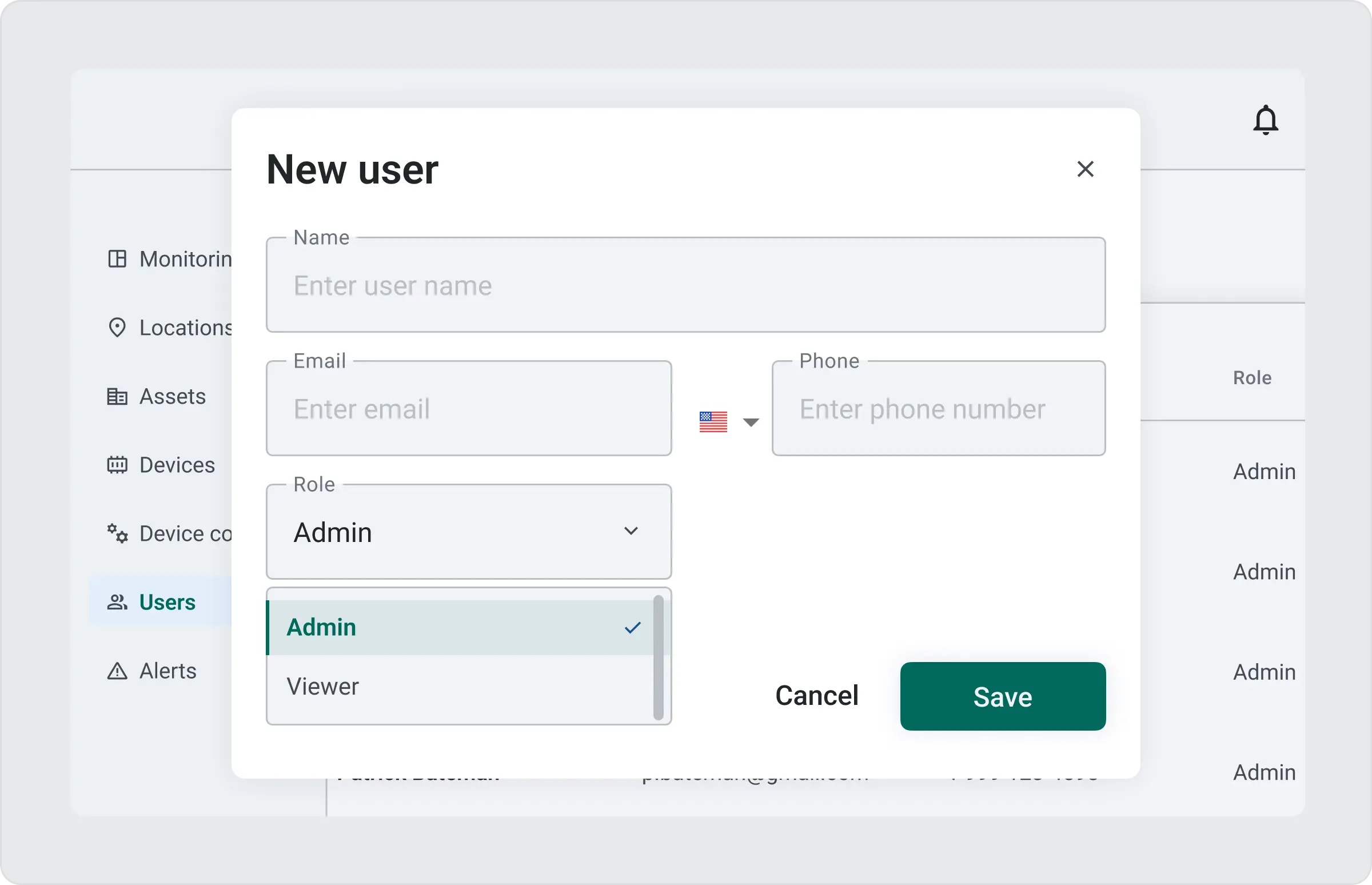

User Management

Different people might need access to the tank level data, but not everyone should have the same level of control. The ThingsBoard IoT platform allows deciding who can see or change the data. Using IoT platform gives access to managers and restrict access for others, ensuring that everyone gets the information they need without compromising the system’s security.

Device-Agnostic

The ThingsBoard IoT platform can work with many types of level measurement devices, regardless of who made them or what type of connection they have. This allows you to use the platform without having to buy the same sensors or hardware, which simplifies and lowers the cost of setup.

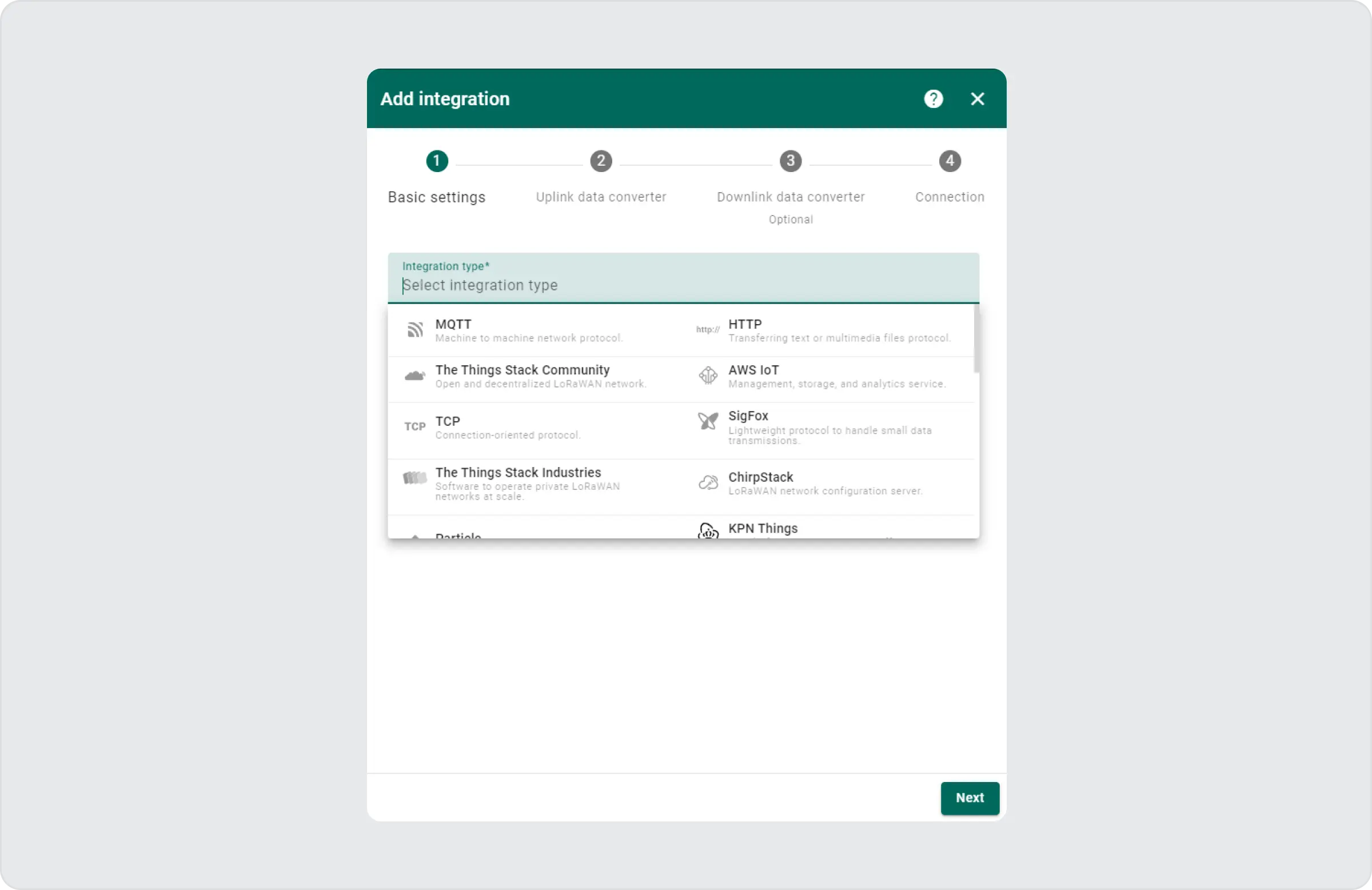

Different Connectivity Options

The ThingsBoard platform supports various ways of connecting sensors to the Internet. Whether devices use Wi-Fi, cellular networks, or specialized options like LoRaWAN (which is good for long distances and open areas), an IoT platform can handle it. This flexibility allows to choose the best connection method depending on where tanks are located and what type of network access you have.

Low-Code Customization for Different Business Requirements and Integrations

Every business has unique needs, and the ThingsBoard IoT platform can be customized to meet those needs. Using ready-made solutions and flexible mechanisms of the platform, you can create unique solutions so that it better matches specific business processes, integrate with other systems (for example, with inventory systems or ordering systems) or add new functions. This makes it easy to adapt the platform to business needs, increasing efficiency and integration with your existing operations.

ThingsBoard Tank Level Monitoring Solution

ThingsBoard Tank Level Monitoring Solution offers real-time insight into oil levels, facilitating proactive management of oil stocks and refining operational workflows. The solution employs advanced technology, including adaptable sensors and robust communication protocols, to accurately track tank oil levels. With intuitive dashboard, users can effortlessly monitor tank state, configure measurement details and custom alerts, and track oil consumption. Mastering oil management processes can diminish operational disruptions and ensure continuous fuel availability, leading to streamlined operations and enhanced customer satisfaction.

Explore capabilities one of the best IoT Visualization Platform

GET ACCESSIndustry oil tank monitoring & Domestic oil tank monitoring

Industry oil tank monitoring

Tank monitoring in the oil, gas and energy industry encompasses a wide range of technologies aimed at optimizing the storage, use and distribution of various oil and bulk materials. This sector requires accurate and reliable monitoring solutions due to the high volumes, potential environmental and safety risks, and economic implications of storage and distribution. Benefits of tank monitoring in the oil and energy industry:

Operational Efficiency: Real-time monitoring allows for just-in-time delivery and distribution, reducing holding costs and optimising supply chains.

Safety and Environmental Protection: Early detection of leaks and potential hazards minimises the risk of accidents and environmental damage.

Cost Savings: By optimising inventory management and reducing the risk of spillage or contamination, companies can achieve significant cost savings.

Data-Driven Decisions: Access to detailed analytics and trends enables better strategic planning and investment decisions.

Domestic oil tank monitoring

Domestic oil tank monitoring involves keeping track of the oil level in home heating oil tanks to ensure a continuous heating oil supplies prevent runouts, and manage oil heating and energy needs expenses more effectively. Benefits of domestic oil tank monitoring:

Convenience: Eliminates the need to manually check the oil tank level gauge, especially in adverse weather conditions or for tanks located in hard-to-reach areas.

Cost savings: By understanding consumption patterns and ordering oil only when needed, homeowners can avoid unnecessary deliveries and take advantage of lower prices during off-peak periods.

Peace of mind: Automatic alerts prevent supply disruptions by ensuring a continuous supply of fuel oil.

Environmental impact: Effective monitoring and tracking of consumption can lead to reduced energy consumption and carbon dioxide emissions by avoiding overfilling of tanks and optimising heating efficiency.

Conclusion

Oil tank level monitoring system is an important tool for effective inventory management and safety. It uses advanced sensors and Internet of Things (IoT) platforms to accurately measure oil levels, providing real-time monitoring. Remote access via IoT Platform increases management convenience, especially for tanks in hard-to-reach locations.

The IoT Platform solution helps to ensure compliance with environmental regulations by detecting oil leaks and preventing pollution, which improves environmental safety. It also provides the ability to analyse historical data and forecast future needs, optimising inventory management and supply planning. Integration with other systems and scalability allow the system to be adapted to specific business needs, ensuring its effective operation at any enterprise.