MANUFACTURING

Fast-paced IoT-Implementation: How Customers of KIOTERA profit from standardized IoT-solutions based on ThingsBoard

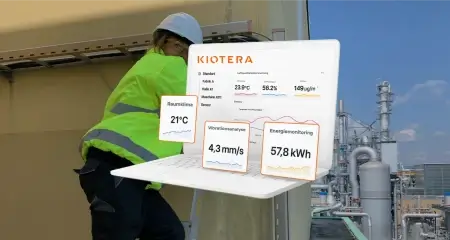

KIOTERA is an IoT integrator that specialises in delivering end-to-end IoT solutions for a diverse range of industries, including chemical parks, the automotive sector, municipalities, and industrial production environments.

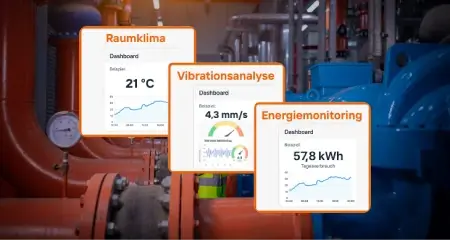

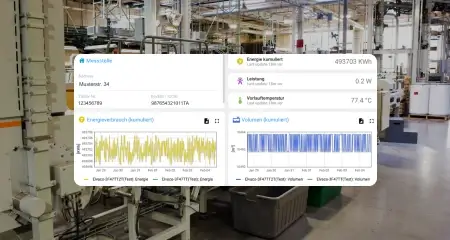

From machine health and energy consumption monitoring to vehicle tracking and the measurement of heat, water and gas usage. Based on numerous implementation projects, KIOTERA has created ready-to-deploy IoT modules with validated sensors, industrial gateways and out-of-the-box visualisations, ensuring customers can start using complete solutions almost instantly. When needed, KIOTERA additionally supplies the LoRaWAN network, allowing rapid deployment of projects without reliance on customer IT.

KIOTERA firmly believes that IoT technologies play a critical role in driving sustainability, enabling more efficient operations, reducing emissions, and creating transparency across distributed assets and infrastructure.