- Architecture

- Prerequisites

- Telemetry Input and Output

- Calculated field configuration

- Rule chain configuration

- Testing

- Performance & Cost Controls

- Troubleshooting

- Next steps

This document describes a ThingsBoard solution that turns raw device telemetry into actionable maintenance insights:

Workflow:

- Devices send

vibration(mm/s),temperature(°C), andacousticDev(% deviation from baseline). - Calculated Fields maintain a rolling window of the last N values (default: 100) and/or last M minutes for each metric.

- The rolling window is forwarded to an AI Rule Node (OpenAI or another LLM provider).

- If the AI detects an anomaly, the rule chain creates a ThingsBoard Alarm and optionally sends a notification.

Architecture

Prerequisites

- ThingsBoard version 4.2+

- Device(s) capable of sending the required telemetry values (for this guide, we will emulate them)

- LLM provider credentials (OpenAI, Azure OpenAI, etc.)

Telemetry Input and Output

Expected telemetry keys (per device):

vibration— mm/s (float)temperature— °C (float)acousticDev— % deviation from baseline (float)

AI Output:

anomaly— short label (e.g.,"Bearing Wear")summary— concise human-readable recommendation (e.g.,"Vibration has reached 7.4 mm/s and temperature is at 86°C accompanied by irregular acoustic patterns, indicating bearing wear. Recommend immediate bearing inspection and replacement to avoid catastrophic failure.")

Calculated field configuration

Purpose: Maintain a rolling window of the last N readings (default 100, configurable) efficiently and forward them directly to the AI node.

Steps:

1. Download and import the EquipmentSensor device profile into your ThingsBoard instance.

2. Download and import the calculated field into the EquipmentSensor device profile.

Key notes:

- Rolling window time range is set to 1 day.

- The number of stored values is set to 100. The default maximum is 1000, configurable in system settings.

- The TBEL script outputs the rolling values in a single message to the rule engine:

1

2

3

4

5

6

// Sample script to output raw values of the rolling arguments;

return {

"acousticDevRecords": acousticDevRecords,

"temperatureRecords": temperatureRecords,

"vibrationRecords": vibrationRecords

};

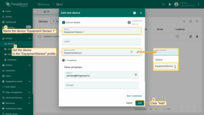

Rule chain configuration

Purpose: Analyze the rolling window data, classify anomalies, and generate a plain-language summary. Works with OpenAI or other LLM providers.

Steps:

- Download the json file with the “Equipment Health Analysis” rule chain configuration.

- Navigate to the "Rule chains" page. Click the "plus" icon button, and select "Import rule chain" from the dropdown menu.

- In the opened window, upload the JSON file with the rule chain configuration and click "Import".

- Locate "AI request" node and enter its edit mode.

- Click "Create new" AI model.

- Enter a name for the AI model, choose the AI provider, and paste your API key. This example uses o4-mini from OpenAI. Test connectivity before saving. Then, click "Save".

- Apply changes to "AI request" node.

- Save rule chain.

5. Update the EquipmentSensor profile to reference the “Equipment Health Analysis” rule chain.

Important details:

- System and user prompts can reference incoming message data:

$[*]— entire message body${*}— entire message metadata$[key]— a specific message body field${key}— a specific metadata value

- Supported response formats: TEXT, JSON, and JSON Schema (we use JSON Schema here).

- A deduplication node with a 5-second interval is used to reduce AI token usage.

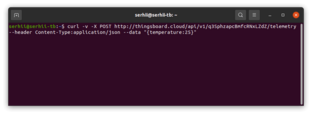

Testing

Step 1. Create a test device Equipment Sensor 1 with the EquipmentSensor profile.

Step 2. Copy the “Check connectivity” command from the device details.

Your command will look something like this:

1

2

3

curl -v -X POST http://localhost:8080/api/v1/6sED1ALqyJg0P6ezIODH/telemetry \

--header Content-Type:application/json \

--data "{temperature:25}"

* Where localhost:8080 is the host of your ThingsBoard instance, and 6sED1ALqyJg0P6ezIODH is the device access token.

Step 3. Modify and send test data.

Step 3.1 No alarm case:

Send the following test data to ThingsBoard. Be sure to replace:

$THINGSBOARD_HOST_NAMEwith the host of your ThingsBoard instance,$YOUR_DEVICE_ACCESS_TOKENwith your device's access token.

1

2

3

curl -v -X POST http://$THINGSBOARD_HOST_NAME/api/v1/$YOUR_DEVICE_ACCESS_TOKEN/telemetry \

--header Content-Type:application/json \

--data '{"vibration":4.2,"temperature":70,"acousticDev":5}'

There won't be an alarm created.

Step 3.2 Bearing wear detection:

Simulate a bearing wear event by sending the following test data to ThingsBoard. Be sure to replace:

$THINGSBOARD_HOST_NAMEwith the host of your ThingsBoard instance,$YOUR_DEVICE_ACCESS_TOKENwith your device's access token.

1

2

3

curl -v -X POST http://$THINGSBOARD_HOST_NAME/api/v1/$YOUR_DEVICE_ACCESS_TOKEN/telemetry \

--header Content-Type:application/json \

--data '{"vibration":8.2,"temperature":88,"acousticDev":5}'

An alarm will be created. Below is an example of the AI output:

1

2

3

4

{

"anomaly": "Bearing Wear",

"summary": "Vibration has reached 7.4 mm/s and temperature is at 86 °C accompanied by irregular acoustic patterns, indicating bearing wear. Recommend immediate bearing inspection and replacement to avoid catastrophic failure."

}

Step 3.3 Misalignment detection:

Simulate a misalignment event by sending the following test data to ThingsBoard. Be sure to replace:

$THINGSBOARD_HOST_NAMEwith the host of your ThingsBoard instance,$YOUR_DEVICE_ACCESS_TOKENwith your device's access token.

1

2

3

curl -v -X POST http://$THINGSBOARD_HOST_NAME/api/v1/$YOUR_DEVICE_ACCESS_TOKEN/telemetry \

--header Content-Type:application/json \

--data '{"vibration":32.2,"temperature":38,"acousticDev":5}'

An alarm will be created. Below is an example of the AI output:

1

2

3

4

{

"anomaly": "Misalignment",

"summary": "A sudden vibration spike to 32.2 mm/s without a corresponding temperature rise or acoustic deviation indicates likely misalignment in the drive train. Please perform an immediate shaft-and-coupling alignment check to prevent further mechanical damage."

}

Performance & Cost Controls

- Batching & debounce: Send to AI only after N points or every T seconds.

- Early filters: Skip AI call if all metrics are comfortably within normal bands.

- Payload compacting: Send statistics (min/mean/max/std, trend) instead of full arrays if prompt allows.

Troubleshooting

- No alarms:

- Verify raw device data is available in ‘Latest telemetry’ tab.

- Enable and browse the calculated field debug events.

- Enable and browse the corresponding rule nodes debug events.

- High costs: Increase the de-duplication period, tune prompt or switch AI model.

Next steps

Experiment with AI prompts and share your feedback with community!